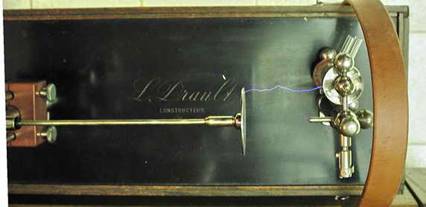

Portable L. Drault Induction Coil f/ X rays

This coil was obtained from

The coil was apparently in

This was a comment supplied by

the originator of the coil:

“Well, the coil was a part

of a small laboratory in

The

coil was used for X rays and was made by L. Drault. Numerous pieces are marked

by the manufacture, the coil top, meters, mercury interrupter armature and top

and the phenolic back and bottom block of the meter post.

The

coil is unique in that it was designed with a mercury interrupter as standard.

The interrupter was driven by the electromagnetic filed generated by the

primary coil of the coil.

The

rectangular piece of metal seen behind the pot is the core of the coil. The

rotor of the interrupter is in alignment with this metal.

The

interrupter has an internal rotor that has two simple spiral tubes inside it.

When rotating, this pumps the mercury up and out the 2 jets. The 2 streams of

mercury make contact with 4 arced pieces of metal mounted underneath the top of

the interrupter. This effectively shorts across the 2 arms on the top of the

interrupter. The mercury allows high currents and quick breaks for a very rapid

coil charging.

The

interrupter gives 4 breaks per revolution corresponding to each arm position of

the external armature.

The

long knob locks the pot in a certain position. The pot was rotated to vary the

speed of the interrupter. It did this by changing the timing of the voltage

applied to the coil in relation to the rotor position. The external swastika

shaped armature is timed to the internal rotor by a set screw in the armature

and a hole in the rotor shaft.

Lubrication

of the rotor shaft is accomplished by a small oil hole thru the hub of the

external rotor which directs the oil to the shaft bearing mounted in the

insulated top.

Situated

inside the wooden mounting base of the interrupter is a condenser connected

across the interrupter.

2

binding posts are also mounted to the interrupter contacts which serve to

connect an external interrupter if desired.

The

2 pet cocks on the interrupter were used to purge the internals of the pot with

coal gas. This was to reduce oxidation of the mercury and components. It was

very important to make sure all air was displaced with gas before operating the

turbine or it could explode! Although the gas was flammable, if there was no

oxygen to sustain combustion, the gas was inert.

Most

portable coils were very simple in that they had a pair of binding posts to

connect the battery. This coil has a complete control panel comprised of an

ammeter, 0-15 ADC, and a voltmeter, 0-30 VDC, a simple lead wire fuse block and

an ON/OFF switch.

The

ammeter is always connected to the coil and the voltmeter has a push button to

temporarily monitor the battery voltage. The voltmeter has a very low

resistance and would drain the battery if left connected, hence the push button

to momentarily place the meter in the circuit.

The

ON/Off switch is interesting in that it is also where the power is applied to

the system. The rectangular slot on top of the switch has a pair of contacts

situated across from each other where the batter power would come in.

The

switch has a red line on one side of the slot to indicate the polarity side of

the battery. If the battery is connected with the + corresponding the red line,

the polarity is correct for the coil and meters. This would make the HV

connections of the coil always be the same polarity as well and simplifies

connecting the X-ray tube.

The

power plug was also the key to turn the coil on. The original plug was missing

so a new plug/ key was fabricated trying to keep the look with the period of

the coil.

The

HV posts for the coil are very interesting in themselves. The bases of both

posts are slotted to lock them in a fixed orientation on the coil top.

The

meter post has a milli-ammeter incorporated in it. The meter was used to

monitor tube current and it is in series with the coil. The meter range is 0-3 ma.

There

is a large hole in the meter post and it is directly in line with a point on

the other post. It is assumed there would have been a spark gap on the coil as

this was a common on X ray coils.

The

gap was set a certain distance to determine the “hardness” of the X ray tube.

When the tube was operating, the gap was set to a certain distance for the

particular X ray work to be done and to determine the hardness or vacuum level

of the tube. For example, most work was typically 3” of spark.

When

the coil was running, the spark gap was adjusted until a spark would pass

across the gap. This distance was what the tube would “back up”. By knowing

this distance, the proper tube could be selected for the desired operation.

A

spark rod was made for this post.

The

second post is very interesting. There is a series spark gap mounted on this

post. All connections seem to have been made after this gap.

Series

gaps were used on induction coils to block inverse currents when the

interrupter was first energized. This inverse was of opposite polarity and much

lower voltage for the X ray tube and can shorten the life of the tube or even

damage it if the inverse was high enough. The gap was set to prevent the lower

voltage from jumping the gap and being applied to the tube and would fire when

the correct and higher voltage was produced from the coil.

This

apparent series gap is adjustable and is enclosed in a glass cylinder with 2

connections. The exact purpose of the connections is not known yet and it is

assumed an inert gas was circulated thru the tube to reduce oxidation of the

metal when the gap was operational. So far, I cannot locate any references to

this particular arrangement.

Of

interest, the posts could not be stored in the coil and it is amazing they

remained with the coil all these years.

One

would be hard pressed to truly call this a “portable” coil. It measures 6 ½”

wide by 22 ¼” long and 10 ¼” tall and weighs 57 pounds without the HV posts and

60 pounds with the posts!

A

suitable battery would have weighed at least 30 pounds. The total outfit with a

tube and stand was probably approaching 100 pounds!

Operation

of the coil would have been something like this:

The

coil was opened and set up with the battery wires connected to the plug and the

X ray tube connected to the appropriate posts of the coil.

The

plug was inserted in the switch and the pushbutton checked to verify the

battery had a good charge.

The

switch was turned on, at this point, the coil is ready to run but there is no

current flowing thru the coil yet.

The

red knob on top of the interrupter is given a quick twist clockwise to pump

some mercury and start the coil. If the twist is fast enough, the coil will

start and the interrupter will run and come up to speed of approximately 700-800

RPM with a quite bump, bump, bump.. noise. This is equivalent to 2800-3200

breaks per minute for the coil.

The

spark gap can be set to verify the resistance of the tube or tubes so the

proper tube can be selected for the desired X ray. At the same time, the tube

can be viewed with a hand held fluoroscopic screen to verify it is operating

properly.

The

switch was turned off to stop the operation.

Once

the system was verified, the patient was placed under the X ray tube and the

desired exposure was made.

Exposure

times could take up to an hour back then and a stop watch was a necessary

accessory to the Dr.’s X ray routine.

This

is a rare find and a thrill to see it operational once again.

Frank

Jones